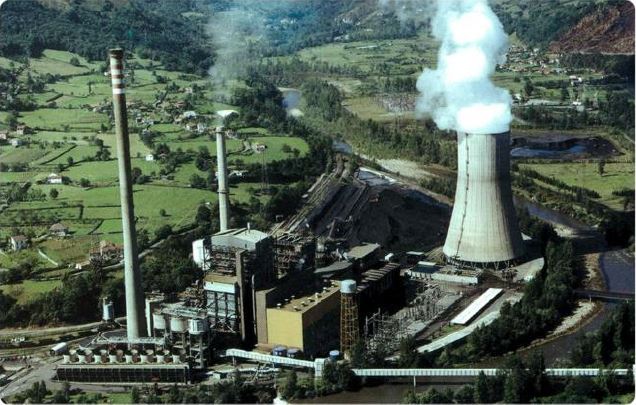

GAS CIRCUIT

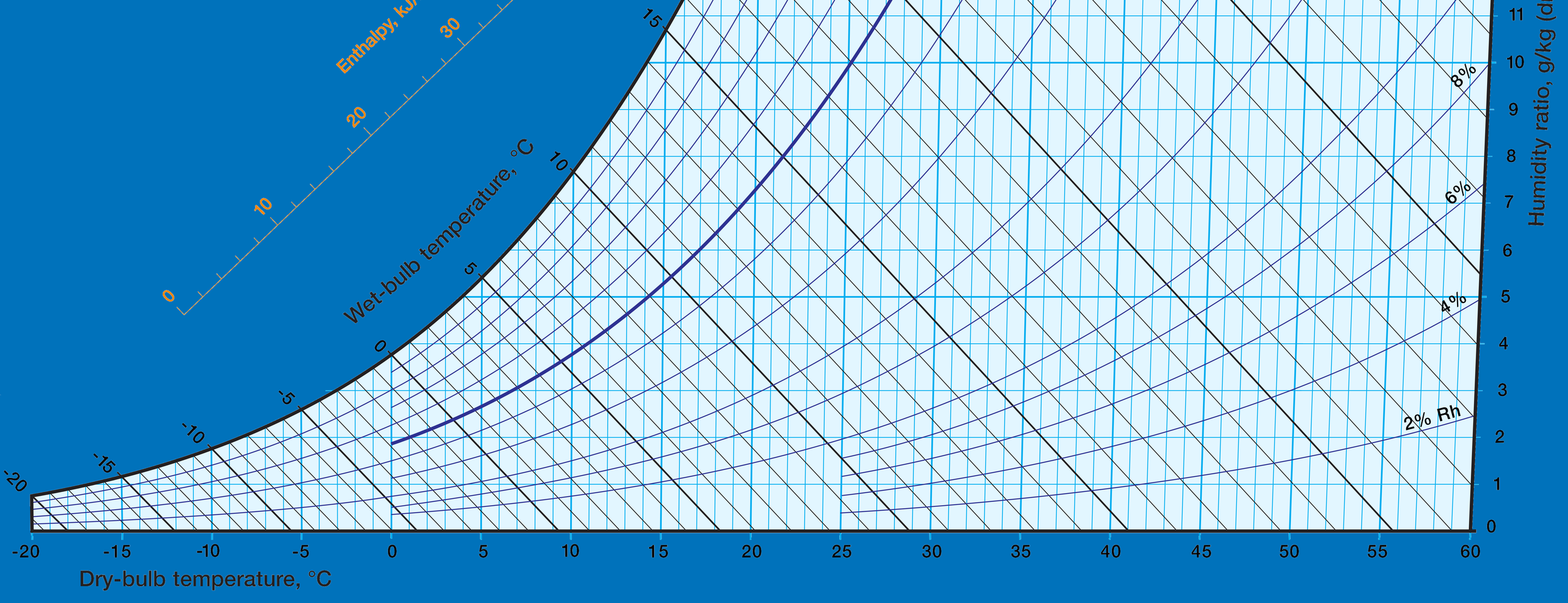

Corrosion is the result of the presence of sulphuric acid. This is less aggressive when its concentration increases: and the concentration increases when the environment is dehumidified. According to the graphs, the relative humidity required is 5%. We have however learned from experience that 20% is enough.

THE RESULTS

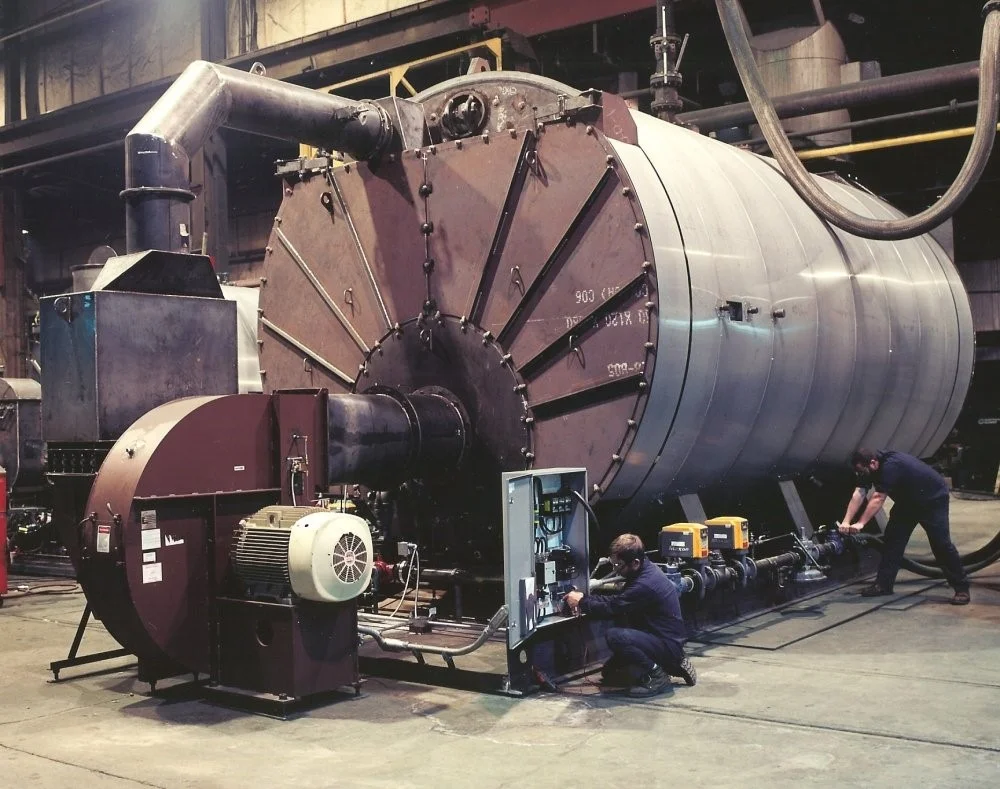

When the dry air method is used, excellent results are achieved:

It is easy to check whether there are corrosion risks, by simply evaluating the humidity in the air outlets.

It enables access to the parts conserved, while they are being protected.

Less energy is required than in the heating method, and no dangerous and expensive chemical compounds are required as for humid conservation.

All the above mentioned points of a technical and economic nature mean the dry air conservation method is preferable to all other possible methods.